Gas Booster Pump & System

We are a 14 years manufacturer of gas booster pump & system in China. Your partner in pressure: Reliable gas boosters, unbeatable value.

- 100% Tested Before Shipping

- Lead Time 2-4 Weeks

- Compatible with all industrial gases (O₂, N₂, H₂, He, Ar, CO₂, etc.)

- Flexible connection standards (CGA, DIN, JIS, customized manifolds)

- Modular design for integration into test benches or lab systems

- Built-in pressure relief & leak protection

- Optional automatic stop logic when reaching set pressure

Standard & Customized Solutions!

CE / ISO9001 / ISO14001 / UL / PED / ATEX / SIL3 Certified Manufacturing

Gas Booster Pumps

Premium Gas Booster Pump Constructed with Aluminum Alloy and Stainless Steel

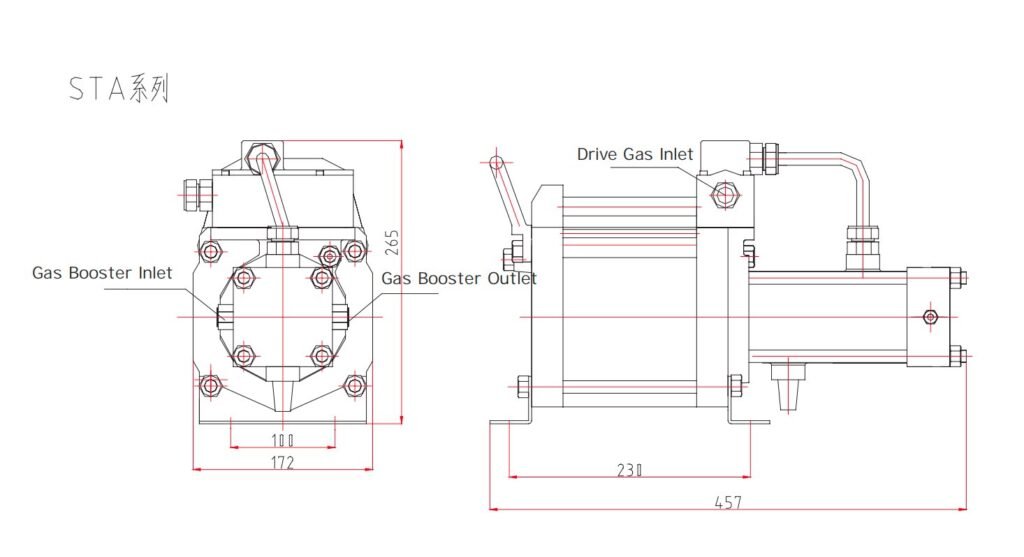

STA Series

- Drive Piston Diameter: 160mm

- Boost Stages: Single-stage

- Action Type: Single

- Input Pressure Range: 1.7-35bar

- Max Output Pressure: 80Mpa

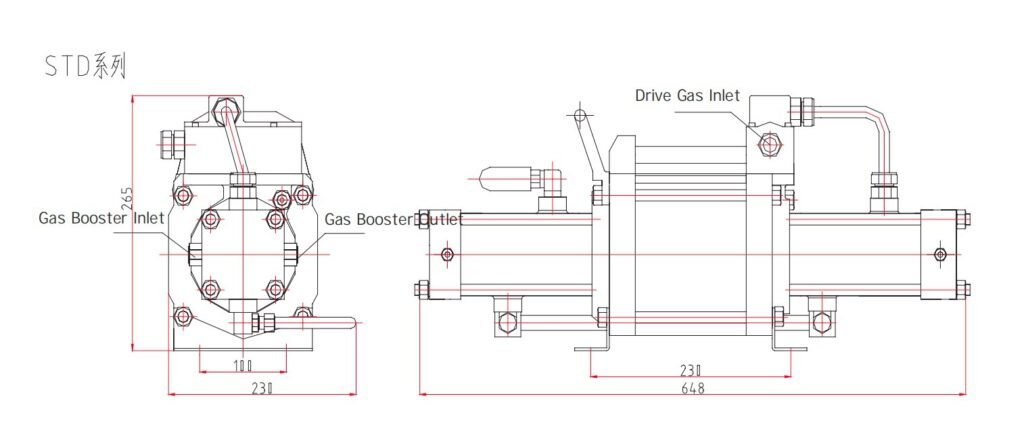

STD Series

- Drive Piston Diameter: 160mm

- Boost Stages: Single-stage

- Action Type: Double

- Input Pressure Range: 5-35bar

- Max Output Pressure: 80Mpa

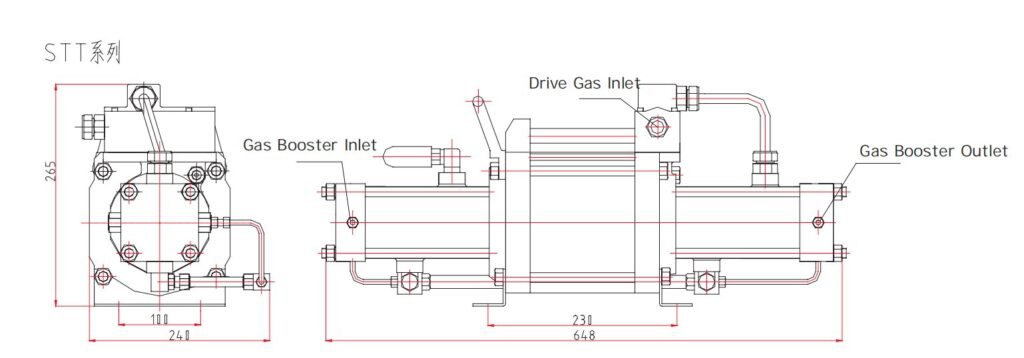

STT Series

- Drive Piston Diameter: 160mm

- Boost Stages: Two-stage

- Action Type: Single

- Input Pressure Range: 0.1-10bar

- Max Output Pressure: 80Mpa

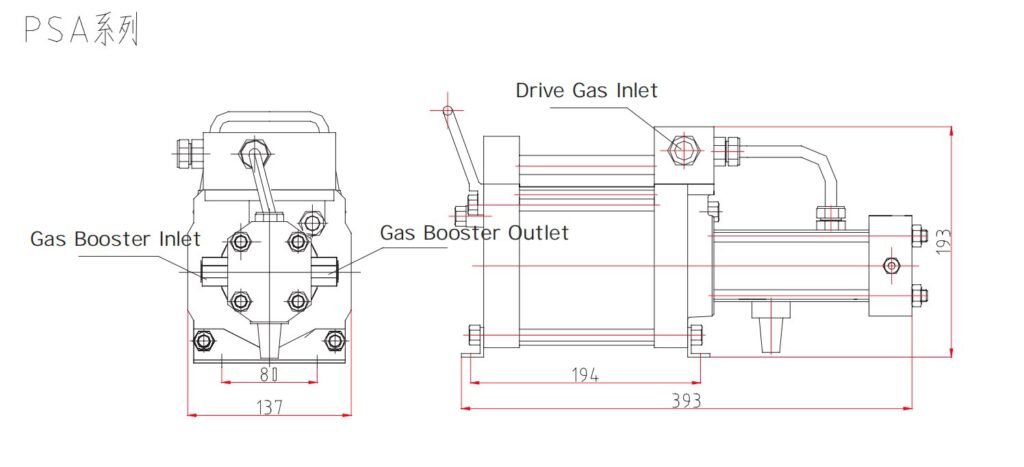

PSA Series

- Drive Piston Diameter: 125mm

- Boost Stages: Single-stage

- Action Type: Single

- Input Pressure Range: 2.1-31bar

- Max Output Pressure: 48Mpa

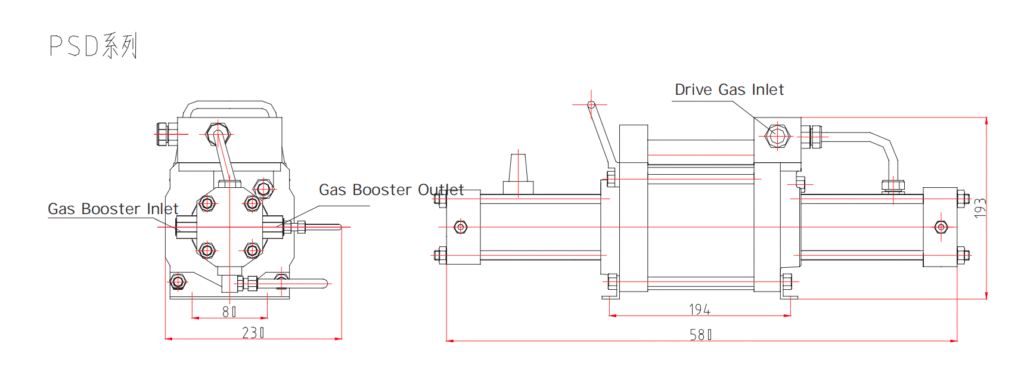

PSD Series

- Drive Piston Diameter: 125mm

- Boost Stages: Single-stage

- Action Type: Double

- Input Pressure Range: 6.8-31bar

- Max Output Pressure: 48Mpa

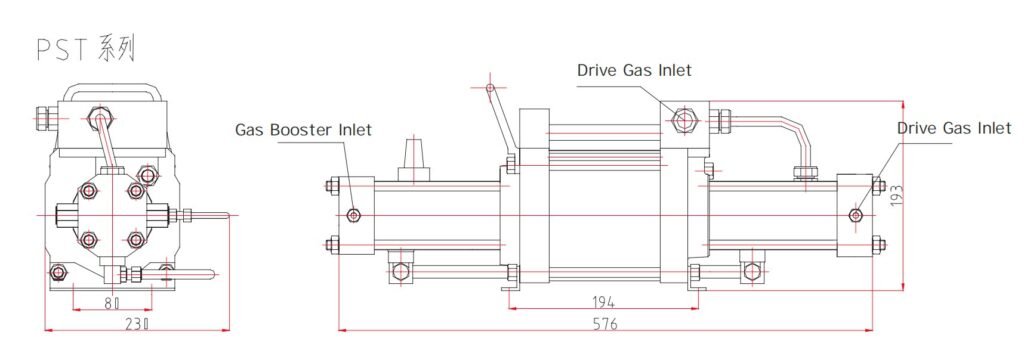

PST Series

- Drive Piston Diameter: 125mm

- Boost Stages: Two-stage

- Action Type: Single

- Input Pressure Range: 0.2bar

- Max Output Pressure: 80Mpa

Air-Driven Refrigerant Booster

The moest advanced equipment for pressurizing refrigerants, designed for recovering and charging eco-friendly refrigerants and liquefied gases like CO₂, Freon, and Fluorocarbon.

Custom Gas Booster

Tailored for Your Pressure & Flow Needs. Achieve Precision, Safety, and Reliability. Contact Us Today for a Bespoke Solution!

Specifications

Note: PA (Port A) = gas inlet pressure; PB (Port B) = gas outlet pressure; PL (Port L) = drive port pressure

Single-acting, single-stage booster with 160mm piston. Uses pneumatic valve control. All-stainless construction with imported seals. Ideal for standard gas boosting applications. (≤8bar drive)

| Model | Pressure Ratio | Min. PA (bar/psi) | Max. Allowable PB (bar/psi) | PB Calculation Formula | Port Size (Drive / Inlet / Outlet) | Max. Flow Rate LN/min (PL=6 bar) | Net Weight (Kg) |

|---|---|---|---|---|---|---|---|

| STA02 | 2:1 | 1.7 / 24.65 | 16 / 232 | 2PL | G 1/2 / ZG 1/2 / ZG 1/2 | 960 (PA=6 bar) | 17.5 |

| STA05 | 5:1 | 3.5 / 50.75 | 40 / 580 | 5PL | G 1/2 / ZG 1/2 / ZG 1/2 | 360 (PA=6 bar) | 14.3 |

| STA06 | 6:1 | 4.5 / 65.25 | 48 / 696 | 6PL | G 1/2 / NPT 3/8 / NPT 3/8 | 110 (PA=6 bar) | 13.8 |

| STA10 | 10:1 | 5.5 / 79.75 | 80 / 1160 | 10PL | G 1/2 / NPT 3/8 / NPT 3/8 | 196 (PA=20 bar) | 13.8 |

| STA25 | 25:1 | 10 / 145 | 200 / 2900 | 25PL | G 1/2 / NPT 1/4 / NPT 1/4 | 81 (PA=20 bar) | 13.8 |

| STA40 | 40:1 | 15 / 217.5 | 320 / 4640 | 40PL | G 1/2 / NPT 1/4 / NPT 1/4 | 49 (PA=20 bar) | 13.8 |

| STA60 | 60:1 | 25 / 362.5 | 480 / 6960 | 60PL | G 1/2 / NPT 1/4 / NPT 1/4 | 61 (PA=40 bar) | 13.8 |

| STA100 | 100:1 | 35 / 507.5 | 800 / 11600 | 100PL | G 1/2 / NPT 1/4 / M14×1.5 | 24 (PA=20 bar) | 13.8 |

Double-head version of STA series. 160mm piston, single-stage boosting to 80MPa. Requires pre-boosted input. Features dual-end cooling and customizable port connections.

| Model | Pressure Ratio | Min. PA (bar/psi) | Max. Allowable PB (bar/psi) | PB Calculation Formula | Port Size (Drive / Inlet / Outlet) | Max. Flow Rate LN/min (PL=6 bar) | Net Weight (Kg) |

|---|---|---|---|---|---|---|---|

| STD10 | 10:1 | 5 / 72.5 | 80 / 1160 | 10PL + PA | G 1/2 / NPT 3/8 / NPT 3/8 | 372 (PA=20 bar) | 19.5 |

| STD25 | 25:1 | 10 / 145 | 200 / 2900 | 25PL + PA | G 1/2 / NPT 1/4 / NPT 1/4 | 154 (PA=20 bar) | 19.5 |

| STD40 | 40:1 | 15 / 217.5 | 320 / 4640 | 40PL + PA | G 1/2 / NPT 1/4 / NPT 1/4 | 92 (PA=20 bar) | 19.5 |

| STD60 | 60:1 | 25 / 362.5 | 480 / 6960 | 60PL + PA | G 1/2 / NPT 1/4 / NPT 1/4 | 115 (PA=40 bar) | 19.5 |

| STD100 | 100:1 | 35 / 507.5 | 800 / 11600 | 100PL + PA | G 1/2 / NPT 1/4 / M14×1.5 | 74 (PA=40 bar) | 19.5 |

| STD100-2 | 200:1 | 35 / 507.5 | 1400 / 20300 | 200PL + PA | G 1/2 / NPT 1/4 / M14×1.5 | 150 (PA=100 bar) | 35.0 |

Two-stage booster handles ultra-low inputs (0.1-10bar) to 80MPa. 160mm piston with dual-end cooling. Perfect for elevating near-atmospheric pressures to extreme highs.

| Model | Pressure Ratio | Min. PA (bar/psi) | Max. PA (bar/psi) | Max. Allowable PB (bar/psi) | PB Calculation Formula | Port Size (Drive / Inlet / Outlet) | Max. Flow Rate LN/min (PL=6 bar) | Net Weight (Kg) |

|---|---|---|---|---|---|---|---|---|

| STT25 | 25:1 | 0.1 / 1.45 | 10 / 14.5 | 200 / 2900 | 25PL + 3.5PA | G 1/2 / NPT 3/8 / NPT 1/4 | 136 (PA=8 bar) | 20.2 |

| STT40 | 40:1 | 0.1 / 1.45 | 10 / 14.5 | 320 / 4640 | 40PL + 6PA | G 1/2 / NPT 3/8 / NPT 1/4 | 124 (PA=8 bar) | 20.2 |

| STT10/60 | 10:1 / 60:1 | 0.1 / 1.45 | 10 / 14.5 | 480 / 6960 | 60PL + 6PA | G 1/2 / NPT 3/8 / NPT 1/4 | 84 (PA=8 bar) | 20.2 |

| STT25/60 | 25:1 / 60:1 | 10 / 14.5 | 25 / 362.5 | 480 / 6960 | 60PL + 2.5PA | G 1/2 / NPT 3/8 / NPT 1/4 | 80 (PA=15 bar) | 20.2 |

| STT100 | 100:1 | 0.1 / 1.45 | 10 / 14.5 | 800 / 11600 | 100PL + 10PA | G 1/2 / NPT 3/8 / M14×1.5 | 63 (PA=8 bar) | 20.2 |

Compact 125mm piston, single-acting design. Shares STA’s valve technology and premium construction. Optimal for space-limited applications requiring reliable boosting.

| Model | Pressure Ratio | Min. PA (bar/psi) | Max. Allowable PB (bar/psi) | PB Calculation Formula | Port Size (Drive / Inlet / Outlet) | Max. Flow Rate LN/min (PL=6 bar) | Net Weight (Kg) |

|---|---|---|---|---|---|---|---|

| PSA02 | 2:1 | 2.1 / 30.45 | 16 / 232 | 2PL | G 1/2 / NPT 3/8 / NPT 3/8 | 206 (PA=6 bar) | 9.0 |

| PSA6 | 5:1 | 4.3 / 65.25 | 40 / 580 | 6PL | G 1/2 / NPT 3/8 / NPT 3/8 | 84 (PA=8 bar) | 9.0 |

| PSA15 | 15:1 | 6.8 / 98.6 | 120 / 1740 | 15PL | G 1/2 / NPT 1/4 / NPT 1/4 | 196 (PA=20 bar) | 9.0 |

| PSA25 | 25:1 | 12.5 / 181.25 | 200 / 2900 | 25PL | G 1/2 / NPT 1/4 / NPT 1/4 | 48 (PA=20 bar) | 9.0 |

| PSA40 | 40:1 | 18.5 / 268.25 | 320 / 4640 | 40PL | G 1/2 / NPT 1/4 / NPT 1/4 | 49 (PA=20 bar) | 9.0 |

| PSA60 | 60:1 | 31 / 449.5 | 480 / 6960 | 60PL | G 1/2 / NPT 1/4 / NPT 1/4 | 61 (PA=40 bar) | 9.0 |

Double-acting version with 125mm piston. Delivers smoother operation and continuous flow. Maintains all premium features of PSA series in dual-action configuration.

| Model | Pressure Ratio | Min. PA (bar/psi) | Max. Allowable PB (bar/psi) | PB Calculation Formula | Port Size (Drive / Inlet / Outlet) | Max. Flow Rate LN/min (PL=6 bar) | Net Weight (Kg) |

|---|---|---|---|---|---|---|---|

| PSD15 | 15:1 | 6.8 / 98.6 | 120 / 1740 | 15PL + PA | G 1/2 / NPT 1/4 / NPT 1/4 | 372 (PA=20 bar) | 12.2 |

| PSD25 | 25:1 | 12.5 / 181.25 | 200 / 2900 | 25PL + PA | G 1/2 / NPT 1/4 / NPT 1/4 | 91 (PA=20 bar) | 12.2 |

| PSD40 | 40:1 | 18.5 / 268.25 | 320 / 4640 | 40PL + PA | G 1/2 / NPT 1/4 / NPT 1/4 | 55 (PA=20 bar) | 12.2 |

| PSD60 | 60:1 | 31 / 449.5 | 480 / 6960 | 60PL + PA | G 1/2 / NPT 1/4 / NPT 1/4 | 68 (PA=40 bar) | 12.2 |

Compact two-stage booster (125mm piston). Elevates pressures from 0.2-10bar to 80MPa. Dual-end cooling. Ideal for low-pressure startups needing extreme output.

| Model | Pressure Ratio | Min. PA (bar/psi) | Max. PA (bar/psi) | Max. Allowable PB (bar/psi) | PB Calculation Formula | Port Size (Drive / Inlet / Outlet) | Max. Flow Rate LN/min (PL=6 bar) | Net Weight (Kg) |

|---|---|---|---|---|---|---|---|---|

| PST25 | 25:1 | 0.2 / 2.9 | 10 / 29 | 200 / 2900 | 25PL + 3.5PA | G 1/2 / NPT 3/8 / NPT 1/4 | 83 (PA=8 bar) | 12.7 |

| PST40 | 40:1 | 0.2 / 2.9 | 10 / 29 | 320 / 4640 | 40PL + 6PA | G 1/2 / NPT 3/8 / NPT 1/4 | 75 (PA=8 bar) | 12.7 |

| PST60 | 60:1 | 0.2 / 2.9 | 10 / 29 | 480 / 6960 | 60PL + 6PA | G 1/2 / NPT 3/8 / NPT 1/4 | 51 (PA=8 bar) | 12.7 |

| PST100 | 100:1 | 0.2 / 2.9 | 10 / 29 | 800 / 11600 | 100PL + 10PA | G 1/2 / NPT 3/8 / M14×1.5 | 38 (PA=8 bar) | 12.7 |

Integrated Gas Booster Systems

Integrated Gas Booster Systems deliver ultra-high pressure gas in a compact, pre-assembled unit. Combining pump, cooling, and controls, they offer plug-and-play operation for testing, industrial, and energy applications requiring reliable and precise pressure.

GBS-I Gas Booster System

The GBS-I unit utilizes compressed air as the driving source to boost process gases such as air, oxygen, nitrogen, argon, and helium.

It is available in two pressure ratios, 2:1 and 5:1, enabling the outlet pressure of the process gas to reach two or five times the inlet pressure.

Application:

- Cutting machines – air supply pressure regulation at the inlet

- Coordinate Measuring Machines (CMM)

- Laser marking machines

- CNC machining centers

- TIG welding machines

- CO₂ welding machines

- Brewery packaging equipment

- Brewery pneumatic valves

- Brewery malt oxygenation systems

- Air-tightness testing machines

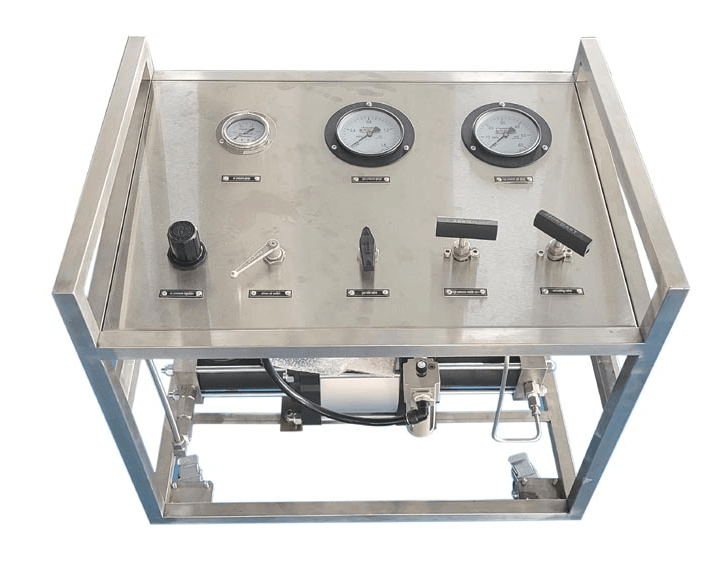

GBS-II Gas Booster System

The GBS-II gas booster system is assembled according to customer requirements, with the gas booster pump and associated components mounted inside a tubular frame or enclosed cabinet. The structure is compact and convenient to use. Pressure gauges, valves, and regulators are panel-mounted for easy operation. The outlet pressure can be adjusted by setting the pressure regulator. When the set pressure is reached, the pump stops automatically and resumes operation when pressure drops.

Driven by 3–8 bar of clean compressed air, the system can deliver outlet gas pressures up to 80 MPa. For higher pressures, double-head booster configurations are available.

Application:

- Static and dynamic testing of aerospace accessories after maintenance

- Safety valve calibration

- Valve and wellhead assembly bubble testing under water

- Automotive brake system testing

- Pressurization equipment for communication cables

- Nitrogen charging for aircraft tires and hydraulic accumulators

- Medium- and high-pressure nitrogen charging for auxiliary injection molding

- Testing of high-pressure gas systems and instruments

- Demineralization processes such as reverse osmosis and desalination

- Providing pressure for testing or calibrating natural gas components

- High-pressure gas flow pattern studies

GBS-III Gas Booster System

The GBS-II gas booster system is assembled according to customer requirements, with the gas booster pump and associated components mounted inside a tubular frame or enclosed cabinet. The structure is compact and convenient to use. Pressure gauges, valves, and regulators are panel-mounted for easy operation. The outlet pressure can be adjusted by setting the pressure regulator. When the set pressure is reached, the pump stops automatically and resumes operation when pressure drops.

Driven by 3–8 bar of clean compressed air, the system can deliver outlet gas pressures up to 80 MPa. For higher pressures, double-head booster configurations are available.

Application:

1.Valve and Pipeline Testing

Strength testing, seal testing, and actuation pressure verification of safety valves, breather valves, and control valves. Pressure resistance and leak testing of pipelines, joints, and hoses.

2.Pressure Vessels and Laboratory Research

Static pressure and burst tests for gas cylinders, hydrostatic/pneumatic vessels. Verification of pressure resistance and pressurization performance for various gases/liquids in R&D. Scientific scenarios requiring real-time display and recording of pressure curves.

3.Aerospace and Automotive Industries

Reliability testing of hydraulic/pneumatic system components in aircraft and spacecraft. Pressure endurance and lifespan testing of automotive fuel lines and brake lines.

4. Fire Protection and Energy Sector

Filling and pressure testing of gas fire suppression systems (CO₂, FM200). Sealing and pressure control tests for natural gas, hydrogen, and liquefied gas equipment.

5.Engineering Companies and Quality Inspection Agencies

Standardized testing of valves, pumps, and pipelines provided by clients in third-party inspection labs. Pre-commissioning pressure debugging and acceptance tests for engineering projects.

Case Study

Boosting Efficiency for an Aluminum Manufacturer

75% Faster Cycle Time: Oven pressurization became significantly faster, eliminating a major production bottleneck. Enhanced Safety: Manual cylinder handling was eliminated, removing a significant workplace hazard. Superior Quality: Consistent, automated pressure control ensured a stable atmosphere, leading to more uniform product quality. Reduced Costs: More efficient gas utilization and lower labor requirements lowered operational expenses.

About YEE VALVE TEST

YEE VALVE TEST specializes in manufacturing high-performance gas booster pumps and integrated systems. We provide reliable pressure solutions for critical applications such as valve testing, cylinder filling, and R&D, enabling our customers to achieve precise control, enhanced safety, and improved operational efficiency in demanding industrial and energy environments.

- Founded in 2012, located in Shanghai

- 10+ R&D, 200+ employees

- 50+ Countries Served

- 5000+ Units Delivered Last Year

YEE VALVE TEST delivers standard and custom gas booster pumps and systems — precision-built to your requirements. Elevate your pressure performance.

Get a Quote Now!

YEE Valve Test delivers precision-engineered gas booster pumps & systems — trusted by professionals in 50+ countries.

✅ 100% tested before shipping

✅ 2-4 week lead time

✅ Custom solutions for your exact requirements

Get Your Free Consultation Today

Copyright © SHANGHAI THINKTANK PROCESS MANAGEMENT CO., LTD. All rights reserved.